Understanding Quartz Slab Shipping: Maximizing Container Capacity for Efficient Transport.

Navigating the world of quartz slab shipping can be as complex as the veins in a premium quartz slab. Whether you’re a seasoned contractor or a first-time importer, understanding the intricacies of container capacity can make or break your project’s budget and timeline. In this comprehensive guide, we’ll unveil the secrets to maximizing your quartz slab shipments, ensuring you stay ahead in the competitive construction and stone import industries.

1. Key factors affecting quartz slab shipping

1.1 Standard container sizes

The most common shipping containers for quartz slabs are 20-foot and 40-foot lengths. Here are their internal dimensions:

- 20-foot container: 5.9 m (19’4″) long, 2.35 m (7’8″) wide, and 2.39 m (7’10”) high.

- 40-foot container: 12.03 m (39’6″) long, 2.35 m (7’8″) wide, and 2.39 m (7’10”) high.

1.2 Quartz slab dimensions

The dimensions of quartz slabs may differ based on the manufacturer and the specific product lines available. Below are the commonly slab sizes:

- Length: 3.20 m to 3.53 m (126″ to 139″)

- Width: 1.60 m to 2.03 m (63″ to 80″)

- Thickness: 1.8 cm (0.71″), 2 cm (0.75″), 3 cm (1.25″)

1.3 Weight limitations

Weight restrictions vary depending on transportation method and location:

- Standard US port restriction: 27,000 kg (59,524lbs)

- Rail/ramps restriction: 21,500 kg (47,399lbs)

- Standard US road limitation: 19,900 kg (44,000lbs) using a tri-axle truck

It is advisable to consult the Department of Transportation in the respective state for specific routes or states, as regulations may differ and are subject to change depending on the location.

Insider’s Tip: Some savvy customers have found a way to maximize their shipments. If you’re located near a port or rail/ramp, you can potentially increase your weight allowance. These customers arrange for the shipping company to deliver containers only to the port or rail/ramp. From there, they hire separate truck companies to make the final delivery. These specialized trucking companies, not affiliated with the shipping lines, are often willing to transport higher weights.

1.4 Quartz slabs packing methods

To safeguard quartz slabs during sea transportation, two main packing methods are utilized: A-frame packing and wooden bundles packing. For customized quartz products such as countertops, vanity tops, table tops, and other prefab quartz items, the preferred packing method is wooden crates.

2. How many quartz slabs fit in a container?

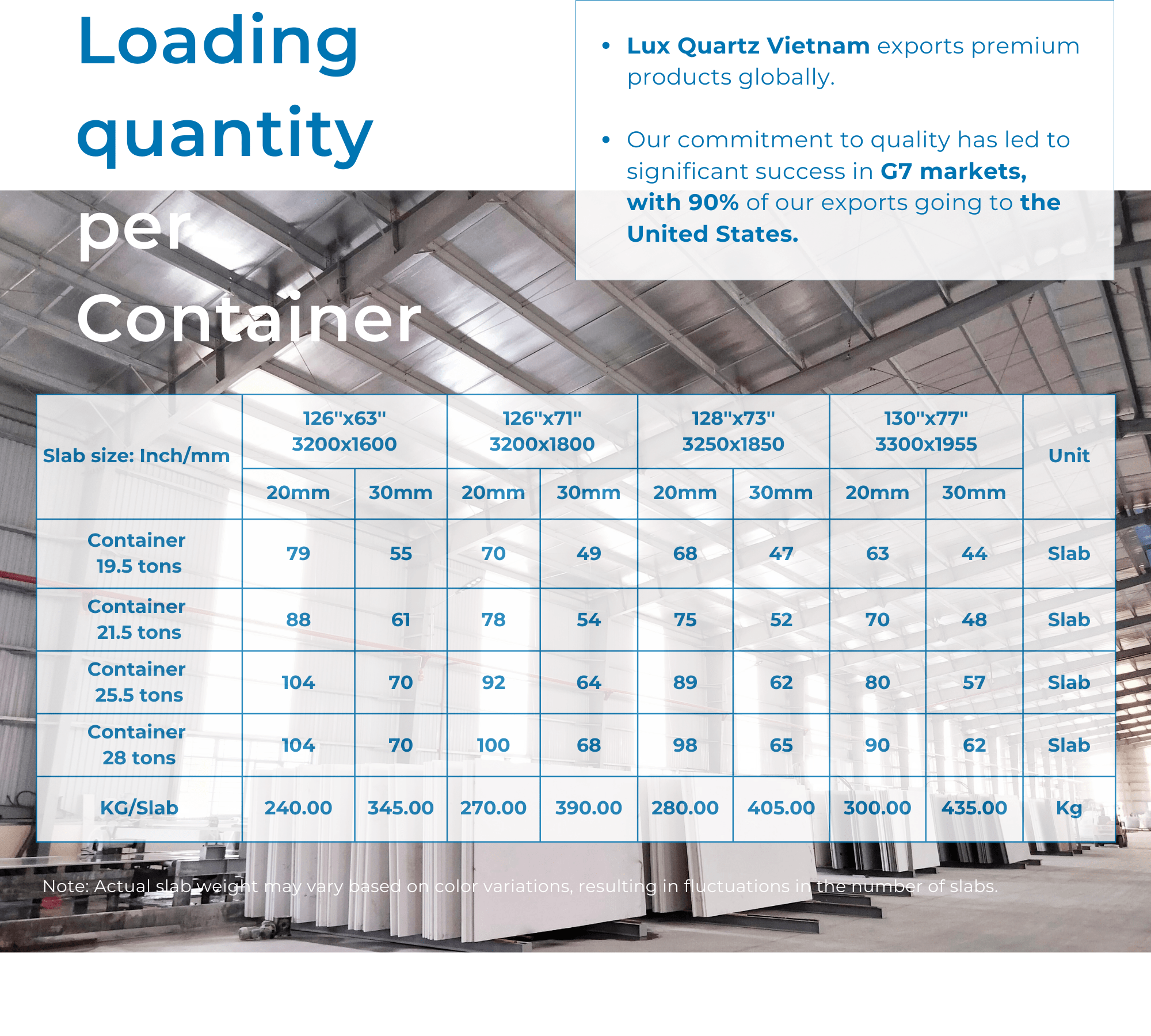

The 20-foot container is the most popular for exporting quartz slabs. The number of slabs that fit depends on their thickness and weight limitations:

For a 20-foot container at the highest weight allowances:

- 2 cm thickness: 8–9 bundles (approx. 90–104 slabs)

- 3 cm thickness: 8–9 bundles (approx. 62–70 slabs)

Maximum weight allowance is 27,000 kg ~ 59,525 lbs.

For standard U.S. road weight limits (19,900 kg / 44,000 lbs):

- 2 cm thickness: 6–7 bundles (approx. 63–80 slabs)

- 3 cm thickness: 6–7 bundles (approx. 44–55 slabs)

Weight allowances vary by transportation method:

- Port delivery: 27,000 kg (59,525 lbs) – Maximum capacity

- Rail ramp delivery: 21,500 kg (47,400 lbs) – Intermediate capacity

- Standard road delivery: 19,900 kg (44,000 lbs) – Standard tri-axle truck limit

The typical road weight limit in the U.S. for tri-axle trucks is 19,900 kg, suitable for customers far from ports or using shipping companies for door-to-door delivery. However, customers closer to ports or rail ramps often request delivery only to those locations, benefiting from higher weight allowances—27,000 kg at ports and 21,500 kg at rail ramps. From these points, independent trucking companies, separate from the shipping lines, are hired for final delivery and usually permit the transport of heavier loads.

3. Optimizing Your Quartz Slab Shipments

To ensure cost-effective and timely delivery of quartz slabs for your projects:

- Consider your specific weight limitations based on your location and transportation method.

- Choose the appropriate container size and packing method for your needs.

- Calculate the optimal number of bundles based on slab thickness and weight restrictions.

- Consult with experienced suppliers who can provide tailored shipping solutions.

4. Why Choose Lux Quartz Vietnam?

Lux Quartz Vietnam is a leading manufacturer and exporter of premium quartz surfaces, combining cutting-edge technology with expert craftsmanship.

At Lux Quartz Vietnam, we’re not just suppliers; we’re your logistics partners. Our commitment to excellence includes:

- Door to Door service: We handle all import-export details, weight considerations, and packing methods.

- Strategic US presence: With distributors in Houston, Texas, we offer immediate slab delivery for faster turnaround times.

- Expert guidance: Our team provides personalized advice to optimize your shipping process.

Whether you’re aiming to become a Lux distributor or looking to purchase premium Lux Quartz in America, we’re here to streamline your quartz slab shipping journey.

Mastering the intricacies of quartz slab shipping can significantly impact your project’s success and bottom line. By understanding container capacities, weight limitations, and strategic shipping options, you’re poised to make informed decisions that can save time and money.

Ready to revolutionize your quartz slab shipping strategy?

Contact Lux Quartz Vietnam today, and let’s explore how we can optimize your imports for maximum efficiency and profitability. Your next successful shipment is just a conversation away!

See more: