In the dynamic world of engineered stone, meeting diverse market demands can be challenging. Whether you’re a stone distributor looking to optimize inventory, a wholesaler seeking reliable supply, a designer in need of custom options, or a contractor facing tight deadlines, finding a quartz slab manufacturer that can meet all these needs is crucial.

At Lux Quartz Vietnam, we’ve developed an effective solution to address these industry-wide challenges. Our approach combines Make-to-Order (MTO) and Make-to-Stock (MTS) strategies, creating a hybrid manufacturing model that offers both customization and quick availability. This unique blend allows us to cater efficiently to the diverse needs of every segment in our industry.

But what exactly are the challenges faced by different players in the engineered stone market? What is MTO and MTS manufacturing? And how does our hybrid approach address these issues? Let’s dive deeper into these questions.

What Are Customer Challenges?

In the engineered stone industry, different market segments face unique challenges that can impact their operations and success. Understanding these challenges is crucial to providing effective solutions. Here are the specific issues faced by our key customer groups:

For Stone Distributors and Wholesalers

- Inventory Management: Struggling to balance stock levels with market demand.

- Product Range: Need a wide variety of designs to meet diverse customer preferences.

- Lead Times: Concerned about long wait times affecting the ability to serve customers promptly.

For Designers

- Customization: Seeking unique, eye-catching quartz designs for standout projects.

- Sample Availability: Need quick access to samples for client presentations.

For Contractors and Construction Professionals

- Project Timelines: Facing tight deadlines that require quick turnaround on orders.

- Consistency: Need assurance of consistent quality and supply for large-scale projects.

What is MTO and MTS in Quartz Manufacturing?

Make-to-Order (MTO) in Quartz Manufacturing

MTO is a production strategy where we start manufacturing quartz slabs only after receiving a customer order. This method is crucial in the engineered stone industry for several reasons:

- Customization: Allows for unique quartz slab designs and specifications.

- Inventory Efficiency: Reduces the need for large finished goods inventories.

- Waste Reduction: Minimizes overproduction of quartz slabs.

Make-to-Stock (MTS) for Quartz Slabs

MTS involves producing quartz slabs based on anticipated future demand. In the engineered stone sector, this approach offers:

- Quick Delivery: Enables faster shipment of popular quartz slab designs.

- Cost Effectiveness: Allows for larger production runs of standard quartz patterns.

- Consistent Output: Optimizes the quartz slab manufacturing process for steady production.

When choosing a quartz supplier for your projects, it’s crucial to understand how different manufacturing approaches can impact your business. Let’s compare how working with a Made-to-Order (MTO) factory differs from partnering with a Made-to-Stock (MTS) supplier:

| Aspect | Working with MTO Factory | Working with MTS Factory |

|---|---|---|

| Product Customization | High – Tailored to specific project needs | Limited – Standard designs only |

| Delivery Time | Longer – Production starts after order | Quicker – Products ready to ship |

| Minimum Order Quantity | Often flexible – Can accommodate smaller orders | Usually higher – Bulk purchases preferred |

| Price | May be higher due to customization | Often lower due to mass production |

| Inventory Management | Easier – Order as needed, less stock required | Challenging – May need to stock various designs |

| Design Flexibility | High – Can adapt to market trends quickly | Limited – Restricted to available stock |

| Project Planning | Longer lead times in project timeline | Allows for quicker project execution |

| Best Suited For | Unique projects, luxury designs, specific client requests | High-volume projects, standard designs, quick turnarounds |

As you can see, both MTO and MTS approaches have their advantages and challenges for customers in the quartz industry.

At Lux Quartz Vietnam, we implement a practical approach that combines elements of both MTO and MTS strategies, allowing us to effectively address the varied needs of our customers. This balanced approach helps us mitigate the drawbacks while maximizing the benefits of both methods.

The Lux Quartz Vietnam Solution: A Hybrid Approach for All

Recognizing that different customers have varying needs, our hybrid strategy incorporates the following key elements:

Core MTO Process for Custom Quartz Slabs

- Tailored production of quartz slabs based on specific customer requirements.

- Offers a wide range of customization in colors, patterns, and sizes of engineered stone.

- Allows quick adaptation to market trends in the quartz industry.

MTS Implementation for Popular Quartz Designs

- Maintain stock of frequently ordered quartz slab patterns.

- Analyze historical data to forecast demand for common engineered stone designs.

- Collaborate with regular customers to anticipate future quartz slab needs.

Flexible Quartz Slab Manufacturing Planning

- Optimize production schedules to balance custom and stock quartz slab orders.

- Efficiently allocate resources in our quartz factory.

- Ensure smooth transitions between different quartz slab designs and specifications.

Engineered Stone Inventory Management

- Carefully monitor stock levels of popular quartz slab designs.

- Implement just-in-time principles to minimize holding costs of finished quartz products Efficiently allocate resources in our quartz factory.

- Maintain sufficient inventory to meet expected demand for common engineered stone patterns.

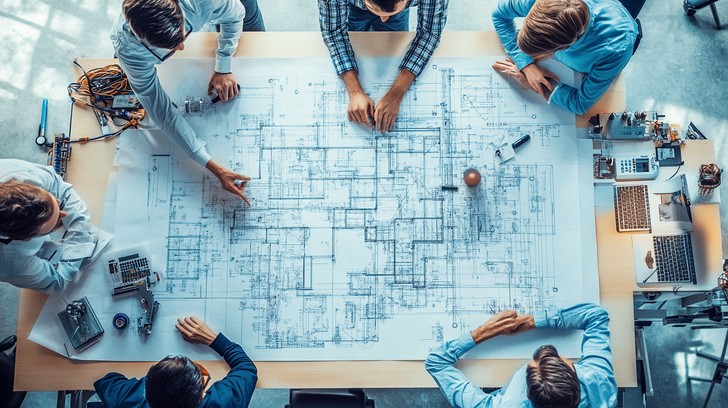

Customer Collaboration in Quartz Slab Production

- Work closely with clients to understand their engineered stone requirements.

- Forecast future quartz slab needs to fine-tune production plans.

- Offer insights into trending designs and innovations in the quartz industry.

How Our Approach Benefits Your Business

By combining the best aspects of Made-to-Order (MTO) and Made-to-Stock (MTS) strategies, we offer a range of benefits that cater specifically to stone distributors, wholesalers, designers, and contractors. Our goal is to not just meet your expectations, but to provide solutions that give you a competitive edge in your respective fields. Partnering with Lux Quartz Vietnam offers significant advantages across all areas of the engineered stone industry. Let’s explore these benefits in more detail:

| Benefit | Stone Distributors & Wholesalers | Designers | Contractors & Construction Professionals |

|---|---|---|---|

| Inventory Management | Tailored stocking plans based on order patterns and needs | Quick access to a wide range of samples | Reduced need for on-site inventory |

| Supply Chain Reliability | Consistent availability of popular designs with custom options | Confidence in product availability for client proposals | On-time delivery for both standard and custom orders |

| Customization | Ability to offer unique designs to end customers | Access to both standard and custom quartz slab options | Flexibility to meet specific project requirements |

| Time Efficiency | Quick delivery of stock items, efficient custom orders | Rapid turnaround on sample requests | Faster project execution with quick delivery options |

| Quality Assurance | Consistent quality across all products | Reliable partner for recommending products | Consistent quality for both MTS and MTO products |

| Competitive Advantage | Offer both quick delivery and customization to customers | Enhanced creative freedom for unique projects | Simplified sourcing from a single, reliable partner |

Conclusion: Meeting Customer Needs in Quartz Slab Manufacturing

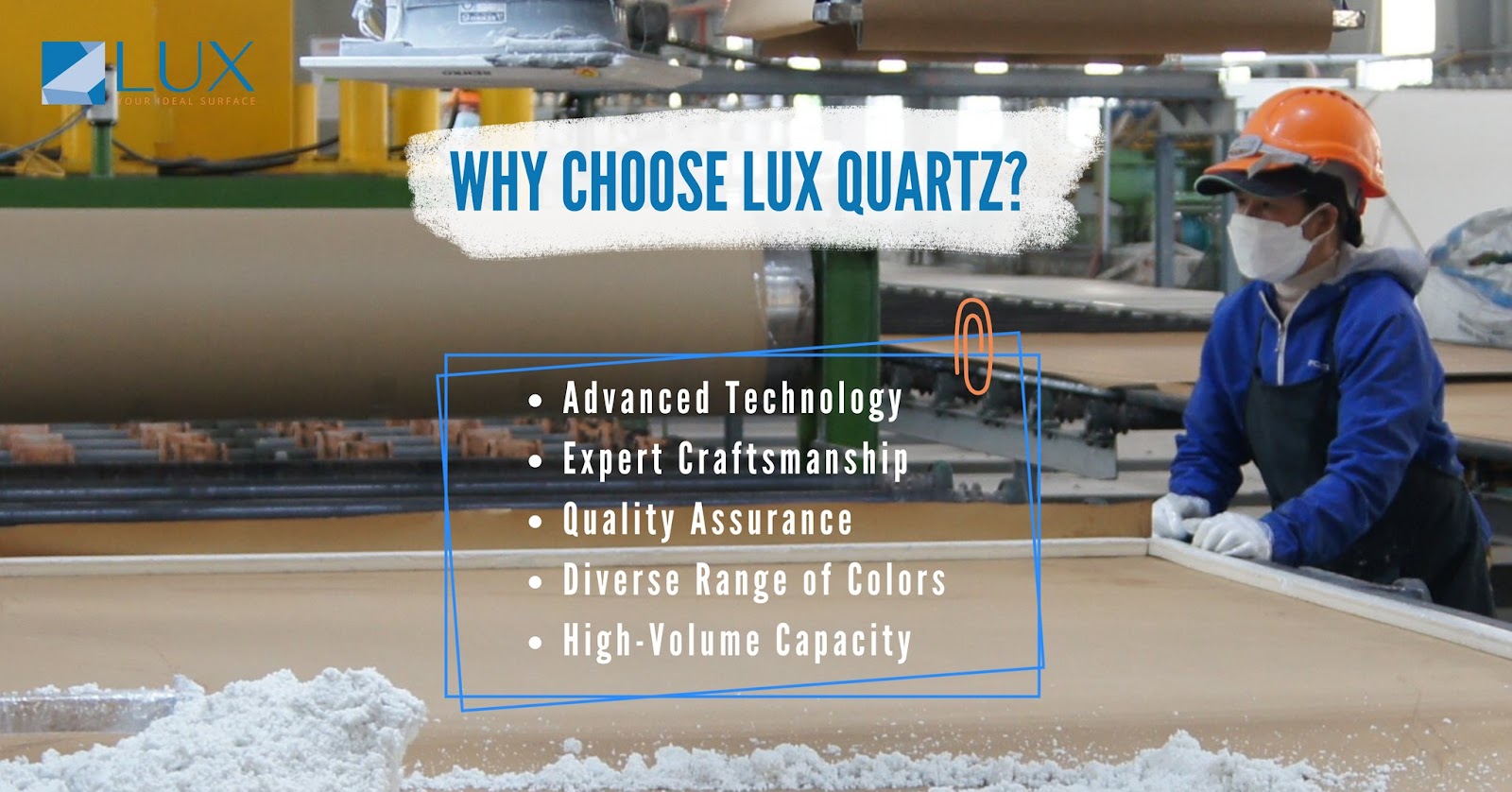

At Lux Quartz Vietnam, we understand the diverse challenges faced by distributors, wholesalers, designers, and contractors in the engineered stone industry. Our practical approach to quartz slab production provides significant advantages in the engineered stone industry. By combining elements of MTO and MTS strategies, we ensure that we can deliver high-quality quartz slabs efficiently, whether for unique projects or recurring orders.

Our commitment to flexibility, quality, and customer satisfaction makes us the ideal partner for all your engineered stone needs. Experience the Lux Quartz difference – where customization meets efficiency, and your unique requirements are always our priority.

Ready to transform your quartz slab supply chain? Schedule your consultation today and discover how Lux Quartz Vietnam can elevate your projects to new heights of success!

See more: