For fabricators, distributors, and contractors who serve a variety of needs, grasping the dimensions of quartz slabs along with the available thickness options is becoming essential. The choice of quartz inventory to stock can either restrict or enhance the services offered, depending on the convenience that standard sizing provides.

At Lux Quartz Vietnam, we have involved experts in stone from different markets and recognize the significance of a strategic approach to sizing that aligns with specific market demands. This guide explores all available quartz slab sizes and how they impact your operations.

- Available Quartz Slab Dimensions

- Business Impact of Large Format Quartz Slabs

- Thickness Options and Applications

- Quartz Slab Sizes and Thickness Impact on Shipping and Costs

- Strategic Inventory Considerations

- Common Sizing Challenges

- Market Trends and Demand Patterns

- Working with Quartz Slab Manufacturer

- At Lux Quartz Vietnam

Available Quartz Slab Dimensions

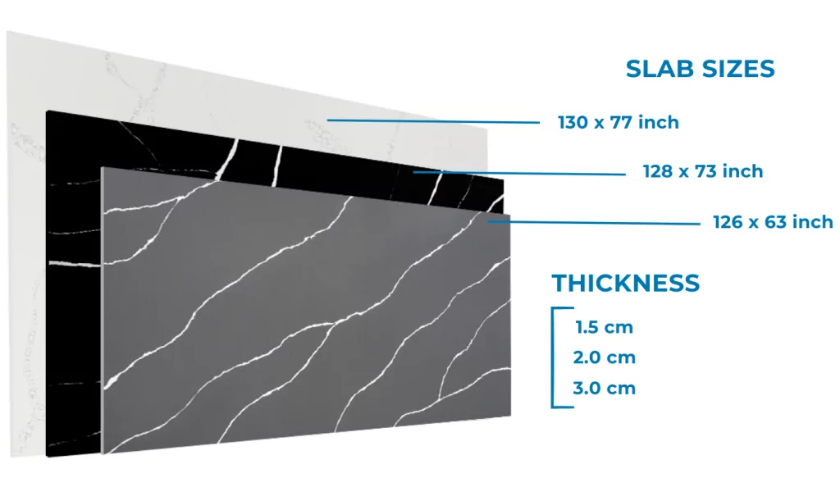

As a dedicated quartz slabs manufacturer, Lux Quartz Vietnam produces engineered stone slabs in several standard sizes to meet various project requirements:

126″ x 63″ (3200mm x 1600mm) represents the industry standard size. These slabs handle most residential bathroom applications and standard kitchen sections efficiently. They offer reliable inventory turnover and suit projects where seaming isn’t a primary concern.

126″ x 71″ (3200mm x 1800mm) provides additional surface area while remaining manageable for fabrication and installation. This size works well for medium-scale residential projects and offers more layout flexibility than standard dimensions.

128″ x 73″ (3250mm x 1850mm) jumbo quartz slabs enable seamless installations for larger residential applications. These large format quartz slabs allow stone fabricators to tackle projects that require continuous surfaces without visible joints.

130″ x 77″ (3300mm x 1950mm) super jumbo quartz slabs deliver the ultimate in seamless design capability. These oversized engineered stone slabs excel in luxury residential applications and commercial quartz slabs installations where uninterrupted surfaces are essential.

What Are Practical Benefits of Jumbo Quartz in Large Rooms?

What Makes Super Jumbo Quartz Slabs Ideal for Large Projects?

Business Impact of Large Format Quartz Slabs

Jumbo quartz slabs provide several operational advantages beyond aesthetic benefits for stone fabricators and quartz distributors. Quartz fabrication becomes more efficient when working with fewer pieces, reducing template complexity and installation time. Projects requiring multiple standard slabs often involve challenging seam placement, while single large format quartz slabs eliminate these concerns entirely.

Material utilization improves with strategic size selection. Well-planned cutting from larger slabs often generates usable remnants for secondary projects, rather than narrow waste strips. This efficiency translates directly to improved project margins.

Customer satisfaction increases when you can deliver the seamless appearances that clients increasingly expect. The visual impact of uninterrupted surfaces often justifies premium pricing, especially in competitive bidding situations.

Thickness Options and Applications

15mm (1.5cm) slabs serve specialized applications effectively. This thickness works well for vertical installations, wall cladding, and furniture applications where weight considerations matter. While not suitable for heavy-duty countertops, 15mm offers cost advantages for appropriate uses.

18mm (1.8cm) provides a middle-ground option that balances strength with weight considerations. This thickness sees moderate demand in specific markets and applications.

20mm (2cm) remains the most requested thickness for residential applications. This dimension handles typical kitchen and bathroom use while maintaining cost-effectiveness. Most residential contractors find this thickness meets their primary project requirements.

30mm (3cm) delivers enhanced durability and enables sophisticated edge profile options. Commercial applications often require this thickness, and luxury residential projects frequently specify it for both performance and visual impact.

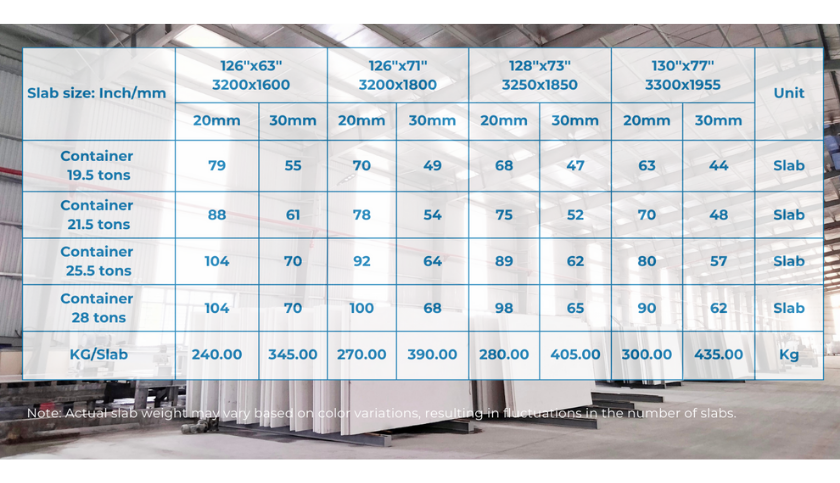

Quartz Slab Sizes and Thickness Impact on Shipping and Costs

Choosing the right quartz slab size and thickness doesn’t just affect fabrication—it also plays a big role in how many pieces fit in a container and what you’ll spend on shipping. Larger slabs may reduce seams but fit fewer per load, while thinner slabs can maximize volume. The table below offers a quick reference to help balance cost, space, and project needs.

Container Loading Guide: How Many Quartz Slabs Fit in a 20ft Container?

Strategic Inventory Considerations

Different business models benefit from different stocking approaches. Residential-focused fabricators typically see strong demand for 20mm thickness in standard to large sizes. Commercial contractors generally require 30mm thickness regardless of surface area.

Market positioning plays a role in size selection. Shops targeting standard residential work can succeed with conventional dimensions, while those pursuing premium markets need larger format capabilities to remain competitive.

Regional preferences influence optimal inventory choices. Some markets show stronger demand for seamless installations, while others prioritize cost-effectiveness over seam elimination.

Common Sizing Challenges

Underestimating the impact of seam placement can cost projects. Even with smaller slabs, strategic planning can minimize visible seaming, but large format slabs eliminate the issue entirely.

Thickness selection affects both performance and perception. While thinner slabs reduce material costs, they may not meet client expectations for premium installations or commercial code requirements.

Transportation and handling requirements increase with slab size. Ensure your fabrication facility and installation crews can manage larger dimensions before committing to jumbo slab inventory.

Market Trends and Demand Patterns

Demand for seamless installations continues growing as clients become more familiar with large-format possibilities through design media and showroom experiences. This trend particularly affects luxury residential and commercial markets.

Commercial renovation activity has increased demand for 30mm slabs, especially in hospitality and restaurant applications where durability requirements are stringent.

Vertical applications using thinner slabs have gained popularity for accent walls and architectural features, creating new opportunities for 15mm inventory.

Guide to Quartz Vein Patterns: From Calacatta to Carrara

Working with Quartz Slab Manufacturer

Successful fabricators often develop strong relationships with manufacturers who understand their market requirements. Look for suppliers who can provide technical guidance on sizing decisions and maintain consistent availability across their product range.

Quality consistency becomes more critical with larger slabs, as any defects affect more surface area. Reliable manufacturing partners ensure the quality standards necessary for successful large-format installations.

Inventory planning support helps balance cash flow with market opportunities. Understanding typical project requirements allows for more strategic stocking decisions.

Choosing the Right Quartz Supplier: How Lux Quartz Vietnam Stands Out

At Lux Quartz Vietnam

We manufacture the complete range of dimensions and thickness options discussed above. Our production capabilities include everything from standard 126″ x 63″ slabs through super jumbo 130″ x 77″ dimensions, in thicknesses from 15mm to 30mm.

Our technical team works with distributors and fabricators to understand their specific market requirements and recommend appropriate product mixes. We maintain consistent quality standards across all sizes and provide the reliability that professional operations require.

Ready to discuss sizing options for your specific requirements? Contact our team to explore how our complete range of dimensions and thicknesses can support your business objectives.