As global attention turns to the health risks of crystalline silica exposure in engineered stone, new regulations and restrictions are emerging in key markets like Australia, the United States, and the United Kingdom. For distributors, wholesalers, contractors, and designers, understanding the evolving landscape of silica bans is crucial when sourcing quartz slabs. So where does Vietnam stand in all of this—and how is Lux Quartz Vietnam offering alternative solutions?

- Countries Restricting Silica in Quartz Surfaces

- Traditional Quartz Slabs, Low Silica, and Silica-Free Surfaces: What’s the Difference?

- Where Vietnam Stands on Silica Regulation

- Lux Quartz Vietnam’s Commitment to Safer Quartz Surfaces

- Smart Questions for Safe and Strategic Sourcing

- Final Thought: Responsible Quartz Begins at the Source

Countries Restricting Silica in Quartz Surfaces

Growing health concerns have prompted governments to take decisive action. In particular, long-term exposure to high levels of respirable crystalline silica dust—especially during dry cutting and fabrication—has been linked to an increased risk of silicosis, a serious and sometimes fatal lung disease.

- Australia is leading the way with a nationwide ban on engineered stone containing crystalline silica, set to take effect on July 1, 2024. The ban covers everything—from production to import and installation

- In the U.S., California has already rolled out emergency safety rules for engineered stone fabrication and is weighing a broader ban. As one of the biggest quartz markets, its decisions could have wide impact.

- United Kingdom and European Union countries are actively reviewing regulations and issuing warnings to fabricators, with expectations of tighter rules ahead.

With this shift in regulations, more buyers are now looking for low-silica or even silica-free With new regulations, more buyers are turning to low-silica quartz — or silica-free surface materials.

Traditional Quartz Slabs, Low Silica, and Silica-Free Surfaces: What’s the Difference?

- Traditional Quartz Slabs typically contain between 90% and 95% crushed natural quartz, a form of crystalline silica. While safe for use in finished form, fabrication processes such as cutting, grinding, and polishing can release fine silica dust into the air.

- Low Silica Quartz Slabs typically contain less than 40% crystalline silica. This composition reduces the risk of harmful dust when cutting, grinding, or polishing.

- Silica-Free Surfaces are engineered to contain little to no crystalline silica—keeping exposure levels within or even below the limits set by emerging regulations, depending on the market.

These safer alternatives offer strong durability, stain resistance, and elegant aesthetics — proving that reduced silica content does not mean lower quality. On the contrary, it reflects innovation and a proactive response to market demands.

Where Vietnam Stands on Silica Regulation

Vietnam currently does not have any bans or export restrictions related to crystalline silica in quartz slabs. However, forward-looking Vietnamese manufacturers are responding to global trends by investing in safer production methods and diversified product lines.

Vietnam has become a competitive and reliable alternative to Chinese quartz supply, offering quality, consistency, and improved communication—all critical factors for international buyers.

Lux Quartz Vietnam’s Commitment to Safer Quartz Surfaces

Safety is no longer just a fabrication concern — it’s now a key selling point.

At Lux Quartz Vietnam, we recognize the shift in global expectations. That’s why our product line includes both low-silica and silica-free slabs to meet the changing needs of our partners across America, Europe, and Australia.

We’re not just focused on beautiful surfaces—we’re committed to offering safer, smarter solutions for the industry.

- Low-silica slabs – These are made with less crystalline silica, helping fabricators stay ahead of new safety standards without compromising on design or performance.

- Silica-free surfaces – For markets with the strictest regulations, we’ve developed alternatives that contain no crystalline silica at all.

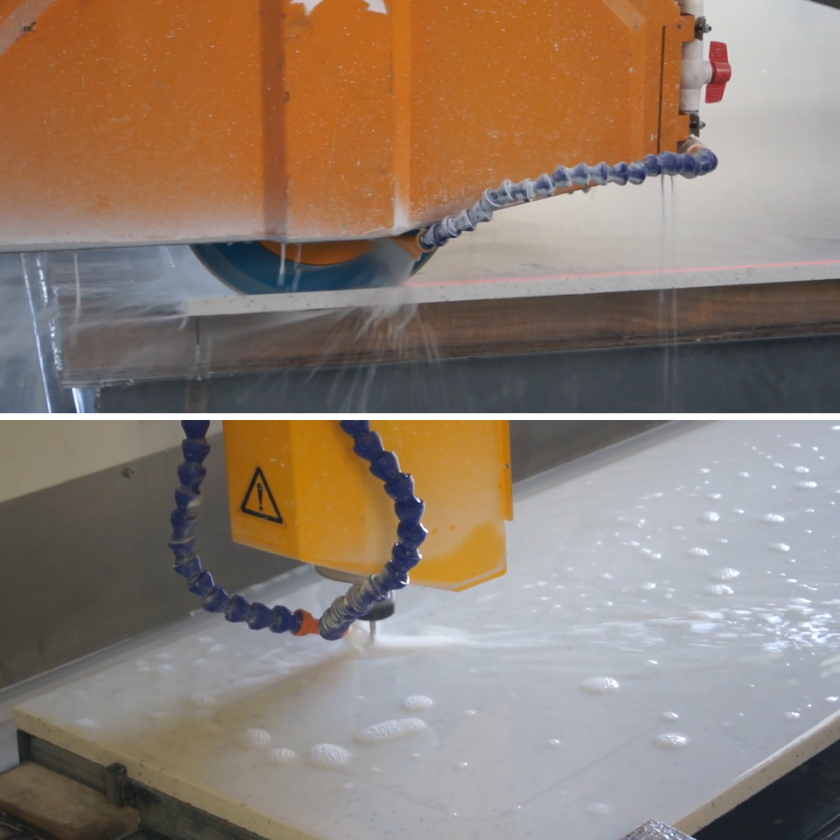

- Safer production – In our factory, we use wet cutting and wet grinding processes to minimize dust and protect the people handling each slab.

- Clear labeling and test documentation: We provide technical data on silica content so customers can make informed decisions.

Choosing low-silica slabs today reduces the risk of future liability, supports employee health, and aligns your business with responsible sourcing practices — all of which appeal to safety-conscious clients and regulators alike.

Whether for distributors looking to protect their supply chains or contractors wanting to stay ahead of regulations, our silica-reduced product lines provide peace of mind and market advantage.

Smart Questions for Safe and Strategic Sourcing

If you import or resell quartz surfaces, it’s time to ask the questions that matter:

- What is the exact silica content of each product line?

- Are low-silica or silica-free options available?

- What safety measures does the manufacturer take in production?

Lux Quartz Vietnam is ready to answer all of these—and more.

In today’s market, it’s no longer enough to ask, “Is this slab beautiful?” Buyers are now asking: “Is this surface truly safe — not just for the kitchen, but for the workers who shaped it?”

Final Thought: Responsible Quartz Begins at the Source

As safety standards tighten and industry expectations rise, partnering with the right supplier is no longer optional—it’s essential. Lux Quartz Vietnam focuses on safety and compliance requirements—delivering low-silica quartz and silica-free surface solutions that meet the needs of today’s responsible builders, designers, and distributors.

Contact our team to explore our full product range, receive technical specifications, or request samples. We’re here to help you stay informed, stay compliant, and stay ahead.