In the world of stone fabrication, not all quartz slabs are created equal — and no one knows that better than the fabricators themselves. While aesthetics matter, what fabricators truly care about often goes far beyond just the look of a surface.

At Lux Quartz Vietnam, we work closely with fabricators across the globe, and we understand the pain points they face daily, from cutting and polishing to installation and customer satisfaction. If you’re in the business, here’s what really matters when choosing a quartz slab you can work with and trust.

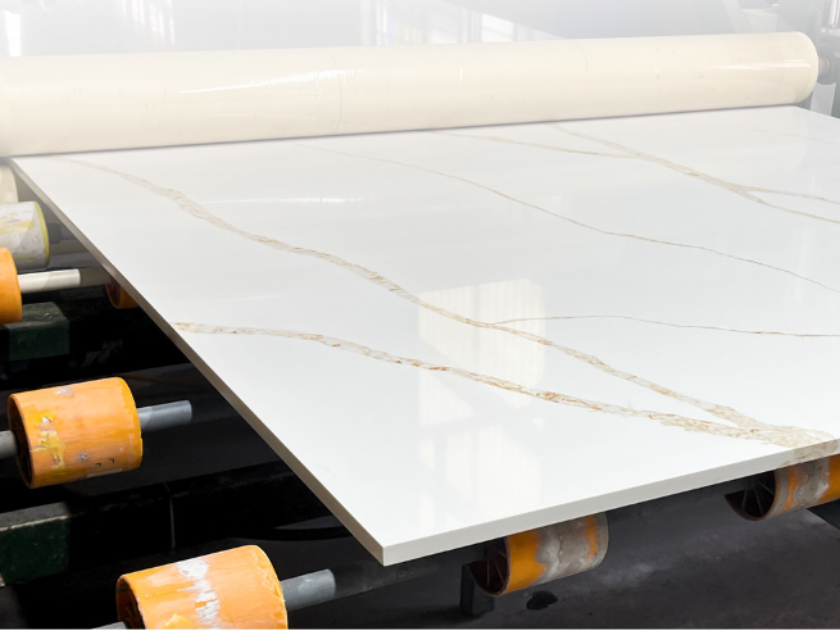

1. Flatness and Thickness Consistency

This is number one for a reason. A slab that isn’t flat or has inconsistent thickness is a fabricator’s nightmare.

When the slab is uneven, the cut may be off. When the thickness varies, joints don’t line up, polished edges look awkward, and the final install becomes a troubleshooting session. It doesn’t just waste time — it hurts the reputation of the fabricator in front of the client.

That’s why top fabricators prioritize tight thickness tolerance and surface flatness. At Lux Quartz, we control slab calibration carefully to ensure every piece matches the specifications — whether it’s 18mm, 20mm or 30mm thickness.

2. Clean Vein Alignment and Natural Flow

Fabricators often need to match veining between cut pieces — especially on L-shape kitchens, waterfall islands, and large vanities. So, when veining looks inconsistent or too artificial, it makes the job harder and the finished look less refined.

That’s why vein layout and bookmatching matter. Fabricators appreciate when the slab not only looks beautiful but is designed with logic and flow, making it easier to align pieces and deliver a high-end look.

3. Ease of Cutting and Edge Polishing

Quartz is durable — but if the resin content or mix is poor, it can lead to chipping, overheating, or dull blades during fabrication.

Fabricators want slabs that are strong yet workable — meaning:

- Edges polish cleanly

- Minimal tool wear

- No hidden air bubbles or weak points

Our slabs are made with over 90% natural quartz and balanced resin, giving fabricators a clean, smooth cut with fewer surprises.

4. Low Breakage Risk During Handling

No fabricator wants to lose a slab during transportation or lifting. Some quartz on the market may look good, but breaks easily due to internal tension, poor curing, or unbalanced filler content.

Fabricators care about structural integrity, especially when they’re working with jumbo slabs. A well-pressed, well-cured slab means less loss, less stress, and more profit.

At Lux Quartz Vietnam, we press and cure slabs under controlled conditions to minimize internal weakness and reduce handling breakage.

5. Reliable Sourcing and Clear Communication

Fabricators often work under pressure — client deadlines, installation schedules, and last-minute changes. The last thing they want is to chase down a supplier for information, or worse, wait on a delayed shipment.

That’s why fabricators prefer working with companies that offer:

- Stable availability of core colors

- Quick response from sales or technical support

- Clear handling, fabrication, and warranty guidelines

Whether you’re a one-man shop or a large fabrication team, communication and reliability go a long way in building trust.

6. Consistent Color from Batch to Batch

Fabricators working on multi-unit projects — or even extending a kitchen installation weeks later — often rely on consistent color and veining across slabs.

Significant variations between batches can lead to visible mismatches, reworks, or dissatisfied clients.

At Lux Quartz Vietnam, we apply strict production controls to help minimize these differences — while still respecting the natural characteristics of quartz sand and other raw materials.

Although no two batches can be exactly the same, we maintain a high standard of visual consistency and quality, allowing fabricators to achieve a cohesive finish across every project.

Why Quartz Slabs Are Not 100% Identical

The Bottom Line: Partnership Over Product

At the end of the day, fabricators aren’t just cutting stone — they’re crafting the centerpiece of someone’s home or project. A reliable, fabricator-friendly quartz slab doesn’t just make their job easier — it helps them build trust with their clients.

At Lux Quartz Vietnam, we don’t just produce beautiful quartz slabs. We build them with the fabricator in mind — from consistent calibration and clean veining to structural strength and dependable service.

We understand the pressure fabricators face on-site. That’s why we focus on:

- Precision flatness and thickness tolerance

- Strong but workable slab structure

- Real-time support and stable inventory

- Slabs that arrive safely — packed, labeled, and ready to work

Whether you’re working on a custom kitchen, a hotel project, or a multi-unit installation, Lux Quartz Vietnam is here to be a steady, long-term partner in your workflow.

Let’s connect. We’re happy to share samples, specs, and support — all tailored to what fabricators truly need.